|

|

metal_miner Kubota swap |

Post Reply

|

Page <1 23456> |

| Author | |

bretto

Member

Joined: 05 June 2010 Location: Orem, Ut Status: Offline Points: 1930 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Nov. 2015 at 1:03pm Posted: 30 Nov. 2015 at 1:03pm |

|

John, that looks like the pivot for a swing out tire carrier with the clamp on the driver side.

I agree with John, neat project, a small diesel as a power plant in one these is a great idea. Should last for a very long time. From the looks of it, when you are done, I bet with your pile of torn off items you will have almost enough to put another Jeep together.  Edited by bretto - 30 Nov. 2015 at 1:23pm |

|

|

|

Lemield

Member

Joined: 18 Jan. 2008 Location: Arvada Colorado Status: Offline Points: 501 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Nov. 2015 at 5:21pm Posted: 30 Nov. 2015 at 5:21pm |

|

Metal_miner...it is looking really nice. Great work.

Regarding the Willys fan noise...I do love the sound of it....but.....the turbo on my Kubota sounds even cooler (to me) and the interior of my Jeep is so much quieter with the Kubota. I was really afraid that I would miss the Willys sound but the turbo singing makes up for it. I can actually carry on a conversation in my Jeep...even with the top up now that there is no fan noise. My Kubota runs ultra cool...around 190 on even the hottest days....

|

|

|

Larry

1949 CJ2A "Little Stinky Green" Kubota Diesel Powered 1970 Chevy C20 454 "Big Red" 1971 Chevy K20 6.2 Diesel "Pumpkin Wagon" 2001 Mercedes CLK320 2003 Cadillac Seville |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Dec. 2015 at 5:15am Posted: 01 Dec. 2015 at 5:15am |

I've actually sold many of the parts to a coworker whose son bought two old flatfenders earlier this year. He's happy and I get $ to "reinvest" in my project. I kept the old frame and fenders for measurement and mock up purposes. I'll eventually get new wheels and tires... But, yeah, over the past few years I have accumulated a few extra parts while deciding on the the scope (creep) of this project.  |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 June 2016 at 12:01am Posted: 19 June 2016 at 12:01am |

|

Work has been extremely busy, so I haven't been getting as much time on my swap as I wanted. However, it gave me a lot of time to think about details I've been spinning my wheels on:

-front shackle angle -engine mounts -fuel tank -transmission crossmember -radiator After a lot of body off - body on - repeat, followed by drivetrain out - drivetrain in - repeat, cutting out and redoing work, I'm ready to post some updates starting with the next post. Edited by metal_miner - 19 June 2016 at 12:57am |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 June 2016 at 12:18am Posted: 19 June 2016 at 12:18am |

|

Front shackle angle:

I screwed up my measurements I gave Jeremy at Throttle Down Kustoms and found that with the drivetrain weight on new suspension, my front shackle angle was too steep. It would probably only get worse when the springs started wearing in.  I cut these mounts off and made new mounts:         |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 June 2016 at 12:32am Posted: 19 June 2016 at 12:32am |

|

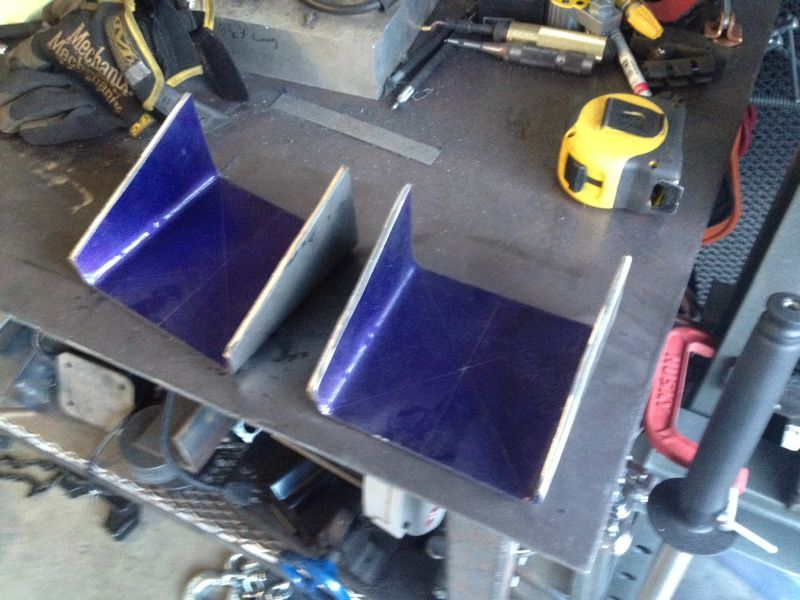

Engine mounts:

I decided to switch to hydraulic engine mounts, so that required making new frame buckets. First, I had to buy a new press courtesy of Harbor Freight coupons and then outfit it with a SWAG weld it yourself press brake kit. I also bought their arbor plates because the cast HF ones are known to shatter under load. Safety First!  I used 3/16 flat bar, laid out the measurements, cut the angles with my SWAG Portaband, and 10 minutes later had these:  I spent about 2 weekends juggling the drivetrain as well as body tub and fenders followed by repeated measurements for angles, firewall and radiator clearances, tacked the mounts in:  After I made new frame buckets, I modified the engine mounts via new holes, filling in old holes, and adding in some lifting brackets:  |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 June 2016 at 12:56am Posted: 19 June 2016 at 12:56am |

|

Fuel Tank:

I want to install a rear fuel tank under the tub. The steel postal jeep tanks are not available anymore so I ordered a plastic tank from MTS. I did a test fit - or shall I say attempted a test fit - and it wouldn't fit in the space because the second to last crossmember, which you can see with a TDK logo cut into it from an earlier post of mine from November, was about 2 inches too close. In addition the rear bumper had a flange on it where the fuel tank skid plate bolts to, which stuck about 1.5" inboard. The plastic fuel tank from the molding process is not a shape with right angles. It bulges out at its seams and therefore takes up extra space. Long story short, I'm going to design a rectangular aluminum tank. I also cut out the TDK crossmember and built a new one out of 0.120 wall 1.5" DOM and moved the new crossmember 3" forward. I installed 3/8 threaded weldwashers from Ruffstuff Specialties in this crossmember as well as in the rear bumper flange for the tank skid plate:    |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 June 2016 at 1:04am Posted: 19 June 2016 at 1:04am |

|

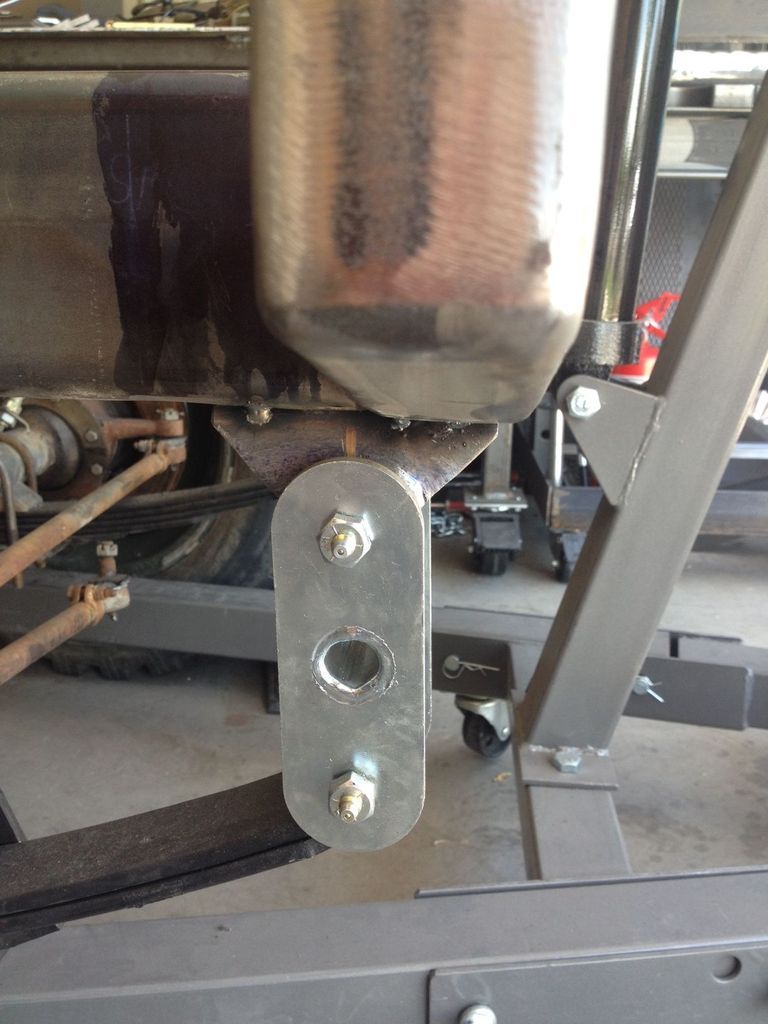

Transmission crossmember:

This part took me 3 months to figure out. In short I built 4 different crossmembers and installed / resinstalled 2 different types of frame brackets before I ended up with a design I was satisfied with. The main sources of causing this much time and energy to be spent was juggling body tub clearance, engine mount redesigns, and clearance against the D18 transfer case torque mount. Pictures of the crossmember will come later, but these are the frame brackets I ended up with:  |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 19 June 2016 at 1:19am Posted: 19 June 2016 at 1:19am |

|

When you look at the following pictures, it's obvious I skipped showing you a few things around the transmission mounting and radiator mounting. I'll explain these in the coming weeks, but the following shows where I am today.

I had coworker's son come over a do finish welding on the various mounts I wasn't confident yet in welding. He had just graduated from trade school so I figure I would give him his first paying job in his chosen career. It's amazing what I learned by stepping back and watching. Later on I had new tips and techniques to practice. Anyhow, some pictures - the crappier looking welds are mine:    Degreased / cleaned frame:  Hoping to paint the frame next weekend:  Hoping this is the last time the drivetrain is out:  |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Feb. 2017 at 2:26am Posted: 22 Feb. 2017 at 2:26am |

|

Greg keeps on reminding me every few weeks to update this

thread so here are some more updates by month.

I then mounted the drivetrain back in the jeep.

|

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Feb. 2017 at 2:38am Posted: 22 Feb. 2017 at 2:38am |

|

Shameless plug!

In September and October 2016 I started working on the hanging pedals. First, I had to beef the firewall. Most people on the forums work with old jeep so they plate the outside of the firewall. I messaged all these folks and asked them how they did it and they all said the old jeep sheetmetal sucks to weld. Because of this I decide to plate from the inside. I used 1/8" plate cut to fit and tried to weld the perimeter to the inner firewall as well as used plug welds. Well, the pictures tell the story. I'm not proud of it, but it's solid. I'll clean up and flatten the outer firewall surface with some epoxy filler.

I searched all over EBAY and bought a few different pedal assemblies to see how I could make them work with minimal modifications in terms of bent and short pedals. I bought Cherokee XJ and Geo Storm assemblies, but soon decided I didn't want to fit hydraulic clutch actuation to my L134 bell housing. So after more searching for manual cable clutch activated pedal assemblies I purchased Suzuki Samurai, Ford Mustang, and Honda Civic assemblies to mock up. I eventually settled on the 88 Honda Civic assembly since it required no pedal arm modifications and it only required a 4" spacer off the firewall for clearance. I also wanted manual brakes and low clearance brake MC so after a lot more research I purchased a brake booster delete from a tuner shop and a MC for an 88 Ford Aerostar. The spacer was built from 3/16 plate and small diameter DOM tube. I will tie the pedal assembly to the dash.

|

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Feb. 2017 at 2:42am Posted: 22 Feb. 2017 at 2:42am |

|

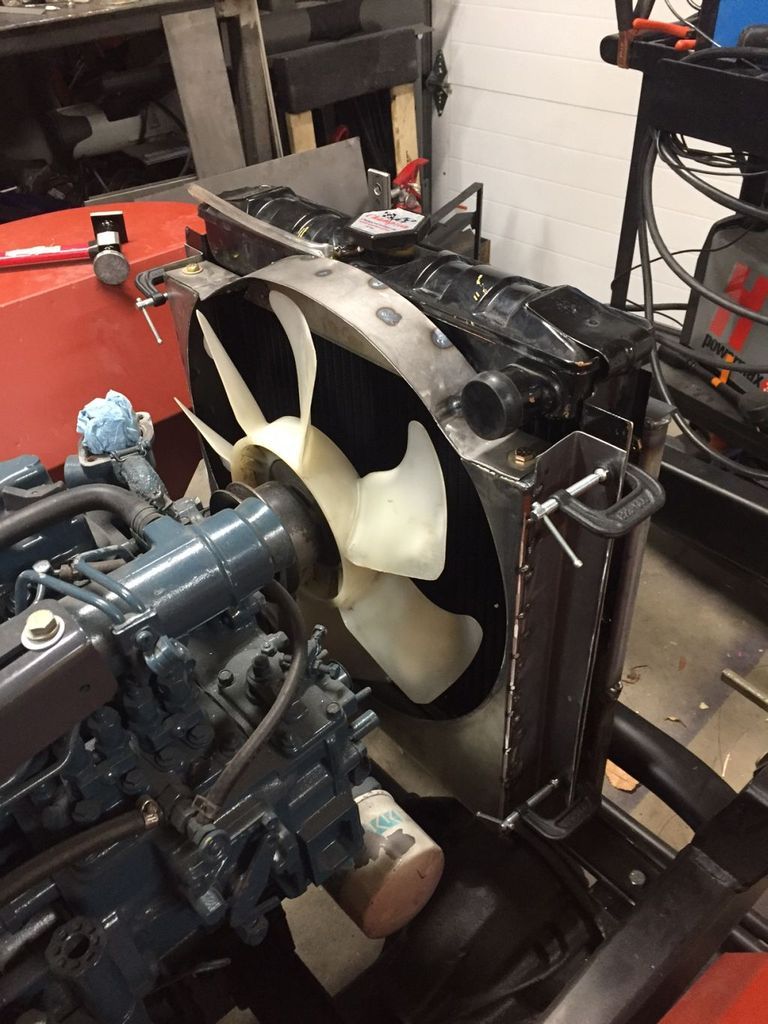

In October 2016, I started working on my radiator and

intercooler mount. After a lot of searching, I decided on a Spectra CU845

radiator. It is for a newer CJ with 4 cylinder engine. The best thing with this

radiator is that it has multiple flanges on it so I instantly visualized how I

could mount it to a detachable frame as well as mount a shroud to it. Once I

received the radiator I used my plasma cutter to trim the flanges. The IC was

purchased from here: http://www.ebay.com/itm/291660453938?_trksid=p2060353.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

The pictures show my THIRD iteration of my radiator mount.

The first 2 versions I got fed up with and trashed because they were too bulky

and heavy. The grill that wraps around the IC inlet and outlet will have rubber edges to cover any sharp edges.

|

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Feb. 2017 at 2:48am Posted: 22 Feb. 2017 at 2:48am |

|

In November 2016 I started on the radiator shroud. This is

my first version built out of 22 gauge plate using my Harbor Freight brake.   I wasn't happy with the first version, so after 3 more iterations I ended up with this in February 2017. It is made out of 18 gauge plate. I used 2.75" tube I split in half length-wise for the forms around the radiator inlet and outlet as well as the crankshaft snout.

|

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

metal_miner

Member

Joined: 11 Aug. 2014 Location: Elko, NV Status: Offline Points: 52 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Feb. 2017 at 3:21am Posted: 22 Feb. 2017 at 3:21am |

|

My next project is to figure out the clutch linkage. I'm going to use a cable operated assembly in conjunction with a design similar to the Advance Adapter chain clutch control.

On another note, one of the reasons this project is taking me so long is that I make 3-4 of something before I like it. I'm also learning this stuff as I go so I usually ruin a few pieces of steel in the process. The positive in this is that I've built up my scrap steel collection. |

|

|

M38. SM465, 3.6 D18, Saturn OD. Soon to be Kubota V2203.

Other toy: 2003 Dodge Cummins with a few mods to 725 HP/1260 TQ. |

|

|

|

Lemield

Member

Joined: 18 Jan. 2008 Location: Arvada Colorado Status: Offline Points: 501 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Feb. 2017 at 5:38pm Posted: 22 Feb. 2017 at 5:38pm |

|

It is looking REALLY good! :)

|

|

|

Larry

1949 CJ2A "Little Stinky Green" Kubota Diesel Powered 1970 Chevy C20 454 "Big Red" 1971 Chevy K20 6.2 Diesel "Pumpkin Wagon" 2001 Mercedes CLK320 2003 Cadillac Seville |

|

|

|

Flatfender Ben

Member

Joined: 13 July 2014 Location: Nyssa OR Status: Offline Points: 2657 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Feb. 2017 at 5:47pm Posted: 26 Feb. 2017 at 5:47pm |

|

Wow awesome work

|

|

|

|

chasendeer

Member

Joined: 24 Feb. 2012 Location: Napa,CA Status: Offline Points: 1086 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Dec. 2019 at 3:29pm Posted: 14 Dec. 2019 at 3:29pm |

|

Any updates?

Thanks Jay |

|

|

|

Triton28

Member

Joined: 25 Mar. 2019 Location: Houston, Texas Status: Offline Points: 149 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Dec. 2019 at 3:35am Posted: 18 Dec. 2019 at 3:35am |

|

Got to love it Photobucket has ruined every picture in this post!

|

|

|

|

Post Reply

|

Page <1 23456> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |