|

|

The Resurrection of CJ2-26 |

Post Reply

|

Page <1 34567 22> |

| Author | ||

Oilleaker1

Member

Joined: 06 Sep. 2011 Location: Black Hills, SD Status: Offline Points: 4412 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar. 2017 at 12:49pm Posted: 14 Mar. 2017 at 12:49pm |

|

|

Huge amount of work to make one tailgate . Cool, but alot of work. I was thinking if someone had the ability to digitalise the "JEEP" and then send it to a CNC machine to make the die, the protruding upper part would have to be smaller and the bottom part bigger so you would end up with a to scale pressing? I'm not educated in this process, but have worked with a artist who made lost wax castings and then a mold. We made silicon bronze tank badges for a old BSA motorcycle. We had to remove the screw hole divots in the mold and drill them by hand. The silicon bronze had shrinkage when cooled that messed up the hole spacing. Nothing is as easy as you think. If only the original gate was around. Back then the thought was it's just a old Jeep piece of junk. Worth 50 bucks to them. Now it's extremely rare. Similar to Willys MA Jeeps, but rarer!!!!! It's in good hands. John

|

||

|

Green Disease, Jeeps, Old Iron!

|

||

|

||

Todd Paisley

Member

Joined: 19 Nov. 2005 Location: Baltimore, MD Status: Offline Points: 362 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar. 2017 at 12:50pm Posted: 14 Mar. 2017 at 12:50pm |

|

|

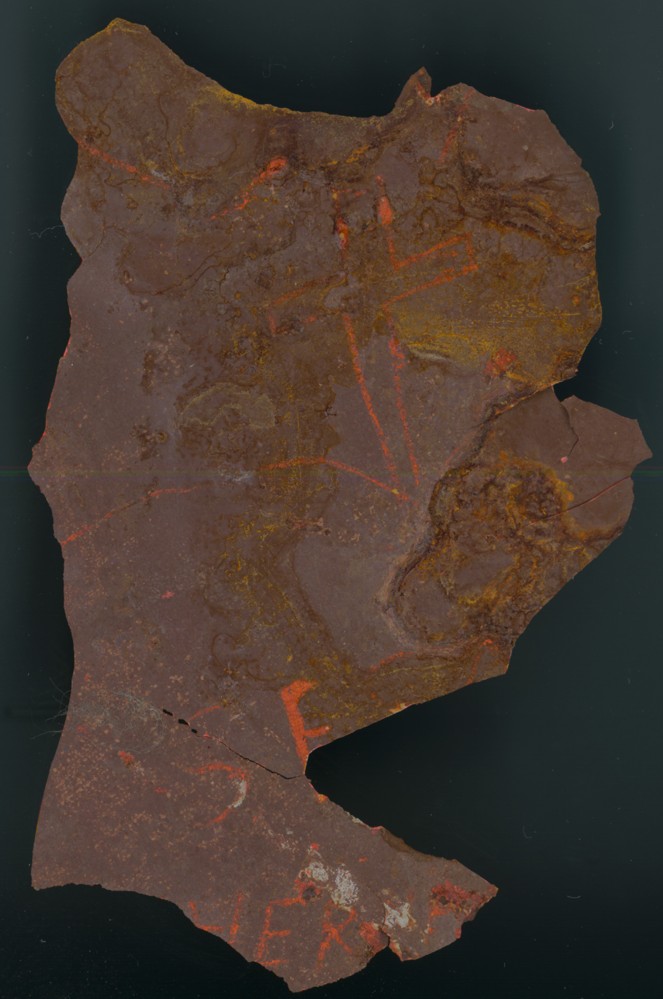

On CJ2-26, there was some orange chalk likes with measurements that appeared to be for aligning the JEEP stamp. Other the years, someone painted underneath the hood. When Fred bought CJ2-26, that paint was flaking off. He sent me the flakes and I put them to together and scanned them and inverted the image to see what it was. I will have to try and dig that out. The measurements could be interpreted as either where to put the hand stamp or where to position it if it was hydraulically stamped. I tend to agree with Jeff that there were hand stamped since the letters are not consistent.

Here is the paint chip:  Never could make it out. Edited by Todd Paisley - 14 Mar. 2017 at 1:05pm |

||

|

Todd Paisley

1941 MB-100063 - MB Factory Test Mule 1942 MB-123136 - Earliest Documented "Civilian" Test Jeep 1944 CJ2-12 - X36 1944 CJ2-16 - X40 1945 CJ2-37 - X61 1945 CJ2A |

||

|

||

Todd Paisley

Member

Joined: 19 Nov. 2005 Location: Baltimore, MD Status: Offline Points: 362 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar. 2017 at 12:57pm Posted: 14 Mar. 2017 at 12:57pm |

|

|

Oilleaker1: What I sent Jeff was a digitization of both the front and back of the JEEP stamp. The problem was that the scanner did not like the shiny paint on it so it isn't crisp. What really needs to happen to do what you want to do is for someone to clean up the scan.

|

||

|

Todd Paisley

1941 MB-100063 - MB Factory Test Mule 1942 MB-123136 - Earliest Documented "Civilian" Test Jeep 1944 CJ2-12 - X36 1944 CJ2-16 - X40 1945 CJ2-37 - X61 1945 CJ2A |

||

|

||

Adrian

Member

Joined: 01 Oct. 2011 Location: New Zealand Status: Offline Points: 1517 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar. 2017 at 6:11pm Posted: 14 Mar. 2017 at 6:11pm |

|

Does the rest of X19 exist, and if so what engine is in it??Adrian |

||

|

1946 CJ-2A Column Change 14605

1973 Saab 96 |

||

|

||

Todd Paisley

Member

Joined: 19 Nov. 2005 Location: Baltimore, MD Status: Offline Points: 362 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar. 2017 at 8:35pm Posted: 14 Mar. 2017 at 8:35pm |

|

|

I am not sure what that engine is. None of the other prototypes had a X number stamped on the engine. They were all based on production MB engines. It may be a coincidence it has the X stamping on it. What would be nice would be to see what the engine assembly date is on this.

|

||

|

Todd Paisley

1941 MB-100063 - MB Factory Test Mule 1942 MB-123136 - Earliest Documented "Civilian" Test Jeep 1944 CJ2-12 - X36 1944 CJ2-16 - X40 1945 CJ2-37 - X61 1945 CJ2A |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 6:02pm Posted: 15 Mar. 2017 at 6:02pm |

|

I did shop this around but nobody wants to touch it ....... and I doubt any CNC shop would. The scanned area was not flat but I cut out most of the mesh surrounding the letters so that I could align the letters to X,Y,Z coordinates: ... The letters may appear angular but that is only because the scan is not perfectly parallel so the wire mesh is also not parallel. I have the letters square,flat, and parallel to the best of my ability. Here are the letters laying down flat: ... as you can see, each letter is taller where the wider vertical pillars are and they actually swoop down over the "E" tines and the hook part of the "J". Here is a sectional view of both "E" vertical pillars: .... the first "E" has a relatively uniform radius of 3/8". The second "E" does not have a uniform radius. It is actually closer to 9/16" to the right, flat on top, and then swoops down to the left. .. very inconsistent. These sectionals are taken from the center of the vertical pillar. They are about a 1/2" long sample, and I cut out the very center where the middle tine intersects. As you can see, the second "E" radius is .015 deeper on the back side of the tine. The second "E" from Fred's sample is also a little flat on top. Here is a better view of this: They are not flat and parallel from top to bottom..... sectional view of the tines: Look at the "E" to the right. It's obvious that the metal was not captured in a two piece die of any precision. ...... and this is just the "E"!  .... our software is not capable of writing a code that is this complex. Perhaps someone else could. I have had problems getting someone to take it on, and that was not even knowing how complex the scan is. Since this is a scan of the windshield skin, which is 28 gauge, and the tailgate is 16 gauge, you could only calculate the outside mold, The inside mold (male) would be inaccurate. Sure, if the letters were square, flat, parallel, and concentric, the new offset could be calculated, but this stamping is far too complex. ... then, how much oversize should the die be to allow for spring back in the metal. I can only guess that some experimentation and failed tests are going to be involved. Even if it all could be done, in the end you would have a perfect die of an imperfect stamp.  If someone here works in this sort of thing, please ping me. If someone here works in this sort of thing, please ping me.I am not a tool maker. When I was experimenting with bows, and canvas tops, I started out by reverse engineering imperfect parts. As I gained experience and after seeing some original drawings, I've changed my approach. Now I analyse the data, but I put lots of focus on what I think the engineer intended the part to look like using the techniques he had to work with and by observing the engineers patterns on other drawings. This one is a tough one I've seen the drawing of the "WILLYS" stamp that has dimensions on the letters. Sure wish there was one on this one. I'll do the best I can with what I have to work with. Since they didn't have CNC machines then, I assume the various depths of the stamping are due to some sort of limitation and unplanned. That, or the die was hand finished. I can make this but I can only make a flat and parallel die that matches what I think the engineers intent was. Still analyzing. |

||

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 6:28pm Posted: 15 Mar. 2017 at 6:28pm |

|

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 6:29pm Posted: 15 Mar. 2017 at 6:29pm |

|

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

Todd Paisley

Member

Joined: 19 Nov. 2005 Location: Baltimore, MD Status: Offline Points: 362 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 6:57pm Posted: 15 Mar. 2017 at 6:57pm |

|

|

Hi Jeff. I think it will take a bit fiddling, but I am sure you can figure it out! Are you sure the horizontal lines of the E are not the same size?

Here is what I found during the thickness measuring of the windshield:  The tailgate:  I can send you the tailgate I want you to stamp and you can cut out the center to get a more accurate measurement.

|

||

|

Todd Paisley

1941 MB-100063 - MB Factory Test Mule 1942 MB-123136 - Earliest Documented "Civilian" Test Jeep 1944 CJ2-12 - X36 1944 CJ2-16 - X40 1945 CJ2-37 - X61 1945 CJ2A |

||

|

||

Jerry45

Member

Joined: 29 Apr. 2007 Location: Cheshire, CT Status: Offline Points: 868 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 7:20pm Posted: 15 Mar. 2017 at 7:20pm |

|

|

I'm finding all of this fascinating! Thanks Fred and Todd!

As the owner of a 1945 CJ-2A, #11802, I'm really interested in how it all turns out! Jerry |

||

|

1945 CJ-2A #11802

1950? Szekley Navy APU Jeep Bantum BTC-3 Trailer "They can have my Jeep when they pry it from my cold, dead hands." |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 7:26pm Posted: 15 Mar. 2017 at 7:26pm |

|

|

||

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

Todd Paisley

Member

Joined: 19 Nov. 2005 Location: Baltimore, MD Status: Offline Points: 362 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 7:59pm Posted: 15 Mar. 2017 at 7:59pm |

|

|

Width. I think the widths of the horizontal lines are the same. My belief/theory is that the stamp was hand done. They may have only made one portion of the die and just beat the metal around it. That would explain the difference in the letters. When they went into production, the obviously used better tooling since the WILLYS was very crisp and uniform.

|

||

|

Todd Paisley

1941 MB-100063 - MB Factory Test Mule 1942 MB-123136 - Earliest Documented "Civilian" Test Jeep 1944 CJ2-12 - X36 1944 CJ2-16 - X40 1945 CJ2-37 - X61 1945 CJ2A |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 8:20pm Posted: 15 Mar. 2017 at 8:20pm |

|

|

In this drawing, the engineer drew the middle tine more narrow:

At first I thought they were all made with the same tool but the center one might not be as deep. I used a depth mic on Fred's castings and it appears that they are approximately the same depth. Can't tell for sure because the stamping is not perfectly flat.

|

||

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 8:36pm Posted: 15 Mar. 2017 at 8:36pm |

|

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

Todd Paisley

Member

Joined: 19 Nov. 2005 Location: Baltimore, MD Status: Offline Points: 362 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 8:36pm Posted: 15 Mar. 2017 at 8:36pm |

|

|

If you do the same for the other E do you get the same dimensions?

|

||

|

Todd Paisley

1941 MB-100063 - MB Factory Test Mule 1942 MB-123136 - Earliest Documented "Civilian" Test Jeep 1944 CJ2-12 - X36 1944 CJ2-16 - X40 1945 CJ2-37 - X61 1945 CJ2A |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 9:01pm Posted: 15 Mar. 2017 at 9:01pm |

|

The vertical post is 3/8" radius, 9/16" wide. ... That's what I'm going with thus far.

|

||

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

Oilleaker1

Member

Joined: 06 Sep. 2011 Location: Black Hills, SD Status: Offline Points: 4412 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar. 2017 at 10:58pm Posted: 15 Mar. 2017 at 10:58pm |

|

|

Schimster, ( Luke Shimmel) has taken a college level course in casting items. What i'm wondering is if you sent him a plaster cast of the inside , could he cast a metal die from that, then smooth it up and use it, and also cast a outside depression die? Or would it simply break when pressed? Again, I'm just throwing out a idea since I have no formal training in this stuff. Oilly

|

||

|

Green Disease, Jeeps, Old Iron!

|

||

|

||

leecarr

Member

Joined: 27 Sep. 2016 Location: Massachusetts Status: Offline Points: 910 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar. 2017 at 12:47am Posted: 16 Mar. 2017 at 12:47am |

|

|

You guys realize that the only person that could even come close to arguing if it's right or not is another one of you guys.

|

||

|

||

Post Reply

|

Page <1 34567 22> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |